Specialty Coated Products

For special applications

JET Tape® “J-10 Series”

The acrylic foam-based, double-sided “JET TapeR” is a flexible tape with high adhesive strength, suitable for a wide variety of industrial applications.

The absence of organic solvents throughout the manufacturing process means that the double-sided JET TapeR is environmentally friendly.

The J-10 adhesive tapes for special applications offer waterproofing, impact resistance and shape adaptation performances.

Features

①Strong adhesion to various types of plastics

The tape also offers strong adhesion to engineering plastic, acrylic, polycarbonate and other resins.

②Excellent shock absorbing and shape adaptation capabilities

With its exclusive substrate structure and high interlaminar strength, the tape offers excellent impact resistance and shape adaptation performances.

③Waterproofing performance (ideal as waterproof sheet; waterproof test: IPX6-7)

The tape is highly resistant to water, offering excellent sealing performance.

④Excellent punching quality

The tape offers proven punching quality in slim bezel applications.

Product range

| Part number | J-1015FM | J-1020FM | J-1030FM | J-1015G | J-1020G | J-1030G |

|---|---|---|---|---|---|---|

| Thickness(mm) | 0.15 | 0.20 | 0.30 | 0.15 | 0.20 | 0.30 |

| Color | White | Gray | ||||

Product data

| Part number | J-1015FM | J-1020FM | ||

|---|---|---|---|---|

| Thickness | mm | 0.15 | 0.20 | |

| Tensile strength *1 | N/cm2 | 114 | 125 | |

| Rupture elongation *2 | % | 850 | 900 | |

| Adhesive strength *3 |

SUS | N/10mm | 12.4 | 13.0 |

| Acrylic | 7.9 | 8.4 | ||

| Polycarbonate | 9.8 | 10.1 | ||

| Holding power *4 | mm | 0.9 | 1.1 | |

| Shear strength *5 | N/㎝2 | 130.0 | 163.0 | |

| Peeling resistance under constant load *6 |

mm | 27.0 | 8.0 | |

Measuring conditions:

- ※1

- Test piece: 25x30 mm. Tensile velocity: 300 mm/min. Maximum tensile strength measured based on the cross-sectional area of the tape.

- ※2

- Test piece: 25x30 mm. Tensile velocity: 300 mm/min. Elongation at rupture calculated based on the original length.

- ※3

- A test piece affixed to 50-um-thick aluminum foil was attached to the joining piece using a 2-kg roller and was left in position for 20 minutes at an ambient temperature of 23°C. The adhesive strength was then measured by pulling the test piece at 90° at a velocity of 300 mm/min.

- ※4

- The holding power was measured at an ambient temperature of 80°C by attaching a 2-kg weight for 60 minutes to the test piece and a piece of SUS bonded together over an area of 20x25 mm.

- ※5

- The maximum shear strength was measured on a test piece and a joining piece bonded together for 72 hours over an area of 15x15 mm by pulling it at a velocity of 50 mm/min.

- ※6

- The peeling resistance was measured on a test piece and a piece of SUS bonded together over an area of 20x50 mm by attaching a 500-g weight at 90° for 60 minutes at an ambient temperature of 80°C.

- ※

- The values in the table above are representative of those typically obtained in Soken tests and can vary in actual applications.

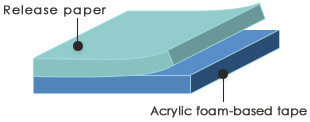

Structure

Taping procedure

- Clean the surface using solvent or other cleaning agents to remove dirt, rust, oil and other contaminants.

- Apply the tape and press it with a finger or a roller to set it firmly in place.

- Remove the release paper. Place the joining piece on the tape and press it firmly with a roller or other means.

Applications

・To fix display bezels on mobile phones and other devices and/or for waterproofing

・To fix engineering plastic parts

“J-77 Series” for joining metals

What is JIS Z1541?

“J-78 Series” for joining plastics

“J-79 Series” for joining at low temperature

“J-10 Series” for special applications

Thermally conductive double-sided adhesive sheets “STC Series”

Double-sided, substrate-free adhesive sheets “STC-2000 Series”

Double-sided, substrate-included adhesive sheets “STC-6000 Series”