Performance Materials (Functional Materials)

Environmentally sound, and weatherability acrylic vehicle

THERMOLAC?

THERMOLAC? acrylic polymer is used as a binder for ink and paint. Various product types are available to fit the needs as weatherability, contamination resistance, chemical resistance and quick drying. Environmentally sound solvent compositions are also available.

THERMOLAC? is available in two types: thermoplastic and polyol

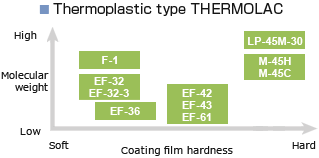

Thermoplastic type

The thermoplastic type features quick drying, adhesion to plastic materials and excellent pigment dispersibility. Many variations are available to match different types of base materials.

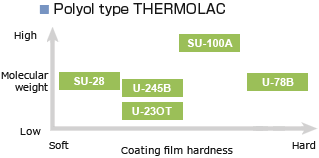

Polyol type

In combination with various polyisocyanates, this type forms a higher quality acrylic urethane layer than ordinary acrylic resin. Acrylic alkyd and one-part curing types are also available.

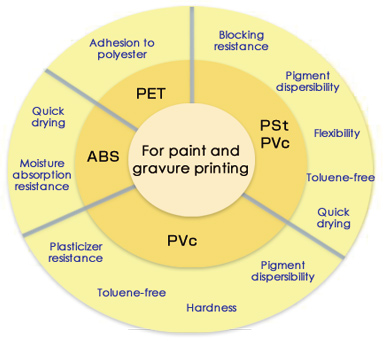

Applications of THERMOLAC?

THERMOLAC? is a vehicle for gravure printing that requires heat resistance, transparency and weatherability. Applications include shrink film for wrapping beverage and food packages, overcoating materials for fancy plywood, and two-part acrylic-modified resin used as plastic and clear paint binder.

Grades (Product names) of THERMOLAC?

■Thermoplastic type THERMOLAC

| Product name |

Solvent type | Non-volatile content(%) |

Viscosity (mPa・s 25℃) |

Acid number |

Number of colors |

IPA dilution |

TG (℃) |

Characteristics | Remarks |

|---|---|---|---|---|---|---|---|---|---|

| EF-32 | Toluene Ethyl acetate IPA |

55 | 4000 to 7500 | 2 > | 4 > | 500 | 45 | Flexibility Carbon dispersibility |

Hydroxyl value 26 |

| EF-32-3 | IPA Ethyl acetate |

45 | 2500 to 6500 | 2 > | 2 > | ― | 47 | Adherence Flexibility |

Toluene-free of EF-32 |

| EF-36 | Ethyl acetate IPA |

50 | 1500 to 2500 | 4 > | 4 > | 320 | 47 | Flexibility Carbon dispersibility |

Hydroxyl value 8 |

| EF-42 | Toluene IPA |

50 | 2700 to 3700 | 1 > | 1 > | 110 | 80 | Drying Blocking resistance |

Hydroxyl value 21 |

| EF-43 | Toluene IPA |

50 | 2000 to 4500 | 7.5 > | 1 > | 250 | 80 | Pigment dispersibility Drying Blocking resistance |

Hydroxyl value 25 |

| EF-61 | Ethyl acetate IPA |

50 | 3000 to 7000 | 1 > | 1 > | 210 | 80 | Pigment dispersibility Toluene-free |

Toluene-free of EF-42 |

| EM | Toluene | 40 | 200 to 400 | 1 > | 1 > | 300 < | 80 | Quick drying Hardness |

|

| F-1 | Toluene MEK |

30 | 50 to 110 | 2 > | 3 > | ― | ― | Adhesion to polyester | Polyester resin |

| LP-45M-30 | Toluene MEK |

30 | 100 to 1000 | 1 > | 1 > | ― | 105 | Hardness Plasticizer migration prevention |

|

| M-45C | MEK | 45.5 | 4000 to 8000 | 6 > | 4 > | 80 | 105 | Flexibility Carbon dispersibility |

Toluene-free of M-45H |

| M-45H | Toluene | 41 | 5000 to 9000 | 6 > | 4 > | ― | 105 | Flexibility Carbon dispersibility |

■Polyol type THERMOLAC

| Product name |

Solvent type | Non-volatile content (%) |

Viscosity (mPa・s 25℃) |

Acid number |

Number of colors |

Hydroxyl value | TG (℃) |

Characteristics | Remarks |

|---|---|---|---|---|---|---|---|---|---|

| SU-28 | Toluene Ethyl acetate |

60 | 1800 to 2700 | 4 to 7 | 2 > | 55 ± 2 | 0 | Blocking resistance Heat resistance |

|

| SU-100A | Toluene Ethyl acetate |

50 | 4000 to 6000 | 1 to 3 | 1 > | 80 ± 2 | 65 | Solvent resistance Quick drying |

|

| U-230T | Toluene | 50 | 250 to 450 | 2 > | 1 > | 30 ± 2 | 31 | Drying | |

| U-245B | Toluene Xylene |

50 | 800 to 1800 | 2 > | 1 > | 45 ± 2 | 30 | Quick drying Solvent resistance |

■One-part curing type THERMOLAC

| Product name |

Solvent type | Non-volatile content (%) |

Viscosity (mPa・s 25℃) |

Acid number | Number of colors | IPA dilution |

TG (℃) |

Characteristics | Remarks |

|---|---|---|---|---|---|---|---|---|---|

| ST-104 | Toluene IPA |

39 | 100 to 200 | 25 to 30 | 4 > | 275 | 42 | Water resistance Gasoline resistance |

Metallic chelate |

| H-210E | Xylene Ethyl Acetate Ethyleneglycol monomethyl ether |

50 | 50 to 80 | ― | ― | ― | ― | Baking at high temperature (Approx. 200°C) |